Replacing Tyres on a Four-Wheel Drive Tractor – What You Need to Know!

Article written by Bush Tyres

When replacing the tyres on any mechanical four-wheel drive (MFWD) tractor it is necessary to take into consideration the mechanical inter-axle ratio of the tractor and only fit tyres with the correct rolling circumference that match the inter-axle ratio.

On all four-wheel drive (4WD) tractors with front tyres that are smaller than the rear tyres, for optimum performance the manufacturer has designed the transmission so that the front wheels rotate faster than the rear wheels. This is known as front wheel lead (or front tyre lead). For your tractor to operate efficiently in terms of traction, the front axle must pull slightly when 4WD is engaged. It is the calculation of the difference in the speed of the front wheels which gives the front axle the “pulling” effect that is called the lead ratio. Front tyre lead is always shown as a percentage.

With mechanical front wheel drive (MFWD) tractors, the rolling circumference of the tyres play a significant role in determining the correct operation of your tractor. When set up correctly, both the front tyres and rear tyres do the work. Too much front tyre lead can cause the front tyres to do too much work and become less efficient. Too much negative lead or lag, can have a braking effect on the front tyres and affect the steering ability. Also, if the ratio between the rolling circumference of the front and the rolling circumference of the rear tyres is incorrect, and the front wheels are turning too fast or too slow, the front tyres will skip or skid and wear rapidly. Additionally, mechanical damage to the tractor’s transmission may occur.

Since the front tyres are smaller than the rear tyres, the front tyres must rotate faster to cover the same distance as the rear tyres. The size ratio of the front tyres to the rear tyres is precisely determined to produce a positive front wheel lead of between 0% and +6%. This lead is specific and may vary depending on the manufacturer of the tractor. So that the front axle rotates faster than the rear axle, the manufacturers of four-wheel drive tractors have designed the transmission with a mechanical inter-axle ratio of between 1.10:1 and 1.60:1. This means that for every complete rotation of the rear axle, depending on the make and model of tractor, the front axle will rotate between 1.10:1 and 1.60:1. Always check tractor manufacturers recommendation as some tractors, for example John Deere require a positive front wheel lead of between +1.5% and +4%.

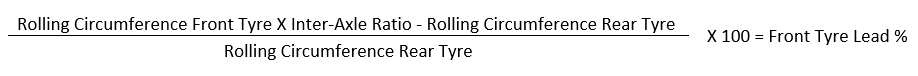

To calculate the front tyre lead you will need to know the rolling circumference of the tyres that you intend to fit and the mechanical inter-axle ratio of your tractor (this is also known as the four-wheel drive factor). The inter-axle ratio figure can be found on the transmission information plate on the tractor, or it is held on a database by the tractor dealer, wheel manufacturer or tyre company. Usually, each tractor model is manufactured with a fixed inter-axle ratio, but John Deere uses various ratios depending on the tractor model and type of transmission. Also, the MFWD transfer gear ratios can be changed during tractor production to match the original equipment tyres.

During the life of your tractor, if you replace the front or rear tyres when they are worn, or when you alter the inflation pressures of your tyres, these changes may cause your tractor’s lead ratio to change. The calculation of the front tyre lead ratio is directly linked to the rolling circumference of the tyres, therefore, if these change for any reason, there will be more or less of an effect on the lead ratio. As your tyres wear, the rolling circumference decreases. If the front tyres wear at the same rate as the rear tyres, then the lead ratio should stay the same. If you replace only the front tyres or only the rear tyres, then the new tyres on one axle will be relatively larger than the worn tyres on the other axle, and this could result in performance issues or mechanical damage as mentioned previously. Likewise, if the tyres are replaced with the same size tyre of a different brand or pattern, the rolling circumferences of the new tyres may be different to the original tyres. Therefore, always recalculate the lead ratio before fitting the new tyres.

In the same way as wear, if the load on the tyres is excessive and the inflation pressure is too low, the effective rolling circumference of the tyre will change. When the load is very heavy or when the tyre inflation pressure is too low, the tyre flattens out at the bottom. This is called tyre deflection. As the tyre flattens out at the bottom the radius between the centre of the axle and the ground decreases. This reduction in the radius of the tyre changes the rolling circumference which may affect the front tyre lead ratio.

With an acceptable lead ratio of between 0% and +6%, if the calculated front tyre lead of the tyres fitted falls in the middle of this range, then any changes to the rolling circumference due to wear, loading or inflation pressures, will allow you to remain within this range. However, if you were close to the upper or lower limit when your tyres were fitted, it is possible that the front tyre lead ratio is no longer within the correct percentage. It is always advisable to recalculate the lead ratio based on the exact rolling circumference of the tyres fitted.

When you replace the tyres on the front or rear of a four-wheel drive tractor, it is advisable to not mix VF (Very High Flexion) or IF (Increased Flexion) tyres with conventional technology tyres. Because the deflection of a VF of IF tyre is much greater than a conventional tyre, even if you fit a tyre of the same size, the rolling circumference of a VF or IF tyre will be much different to the conventional tyre and the front tyre lead will no longer be within the correct range.

If you need help or advice with any of the above, please contact your local Bush Tyres branch or representative.

They will need to know the following information:

a. Tractor – make & model

b. Tractor – year of manufacture

c. Original tyres fitted to tractor – brand, pattern, and load/speed index

d. Replacement tyre size you intend to fit – brand, pattern, and load/speed index

e. Further details may be required

For John Deere tractors the following information is required:

1. Rear diff gear pair: Transmission ratio of the differential gear pair. These values are displayed on the product information plate on the left side of the radiator.

2. MFWD gear pair: Transmission ratio of gear pair for front-wheel drive axle output. These values are displayed on the product information plate on the left side of the radiator.

3. Front axle ratio: Transmission ratio of front axle. This figure is displayed on the front axle type plate.

CALCULATION FORMULA:

Tyres

Tyres Services

Services Fast Fit

Fast Fit Offers

Offers