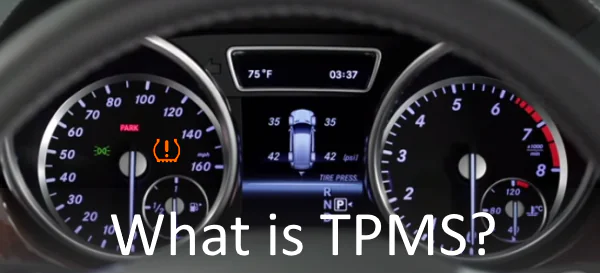

What is TPMS?

Article written by Bush Tyres

The air pressure within your tyres is the most important factor in determining how well they perform.

Pressure affects the tyre’s speed capability, load carrying capacity, handling response, wear rate and overall safety. What is more, under-inflated tyres will cause your car to use more fuel and emit more CO2 emissions.

It’s therefore critical for your safety and comfort that your tyres are properly inflated in line with the vehicle manufacturers’ recommendations. Tyre pressures should be manually checked when they are cold at least once a month or before a long journey.

Click here for more benfits of maintaining correct tyre pressures

However, in order to assist you in monitoring the pressure in your tyres, all new cars are now equipped with a tyre pressure monitoring system (TPMS) which notifies you of any tyre pressure issues.

To discover how your TPMS works and how you need to look after it, take a look at Tyresafe.org’s animation below.

TPMS stands for Tyre Pressure Monitoring System

It’s a system fitted to a vehicle which constantlymonitors the pressures or pressure imbalance in thetyres and provides a warning to the driver if these fallbelow a certain threshold.

Such is the importance of correct tyre inflation, TPMS is avery useful safety feature. However, TPMS should notbe seen as a replacement for regular manual tyre safetychecks.

There are two types of TPMS systems fitted on cars today.

- Direct systems use radio sensors are mounted insideeach wheel to measure the tyre inflation pressures.

- Indirect systems utilise the vehicle’s existing Anti-lock Braking System (ABS) sensors to measure and compare the rotational speedsof the tyres, which are affected by their pressures.For example; a tyre that is of a lower pressure to all the other tyres will rotate faster (when driving in a straight line) because the rolling circumference of the tyre is smaller.

Both system types work with the vehicle’s main ElectronicControl Unit (ECU) to alert the driver via dashboardwarning lights to any pressure loss or variance issues.

TPMS & runflat tyres

Runflat tyres (RoF) are designed to provide a limited run-onperiod following a puncture. These types of tyres canbe identified by the "RF" marking found on the tyresidewall.Runflat tyres are only designed to run for a limitedperiod, at a maximum speed of 50 mph with a limitedload carrying capacity.Due to the nature of runflat tyres, these should onlyever be fitted to vehicles equipped with TPMS.

You can see the identifying marks on runflat tyres by visiting our page which explains which runflat tyres can be repaired.

TPMS Law

Since November 2014, all new passenger vehicles soldin the EU must be equipped with TPMS.Furthermore, with effect from 1st January 2015,all vehicles fitted with TPMS will need to have a fullyfunctioning system when undergoing their annual MOTtest. Inoperative or faulty TPMS systems will result inan MOT failure.

Tyre Pressureand Your Safety

The air pressure within your tyres is the mostimportant factor in determining how well theyperform. Pressure affects the tyre’s speedcapability, load carrying capacity, handlingresponse, wear rate and overall safety. What’smore, under-inflated tyres will cause your carto use more fuel and emit more CO2 emissions.

It’s therefore critical for your safety and comfort thatyour tyres are properly inflated in line with the vehiclemanufacturers’ recommendations.Tyre pressures should be manually checked when theyare cold at least once a month or before a long journey.For more details on how to check your tyre pressures,visit any of our centres for assistance or take advantage of our Free Safety Inspections.

TPMS warning lights

If you are unable to check your pressures yourself,either call for roadside assistance or locate yournearest tyre professional who will be able to help you.

Manual Checks

While the benefits of TPMS are widely recognised, it isimportant that they are not seen as a replacement forregular manual tyre safety checks. Pressures should betested at least once a month or before any longjourney, when the tyres are cold using an accurate andreliable pressure gauge.When checking pressures, it is advisable to also givethe rest of the tyre a thorough visual inspection as wellas ensuring the tread is not excessively or unevenlyworn.

TPMS Servicing

To ensure your TPMS system continues to operateproperly and reduce the likelihood of an MOT failure,it may be necessary to have the system servicedoccasionally. TPMS sensors are designed to last formany years and miles, however, after a certain period,the sensor’s internal battery will run out meaning areplacement is needed.

When replacement TPMS sensors are fitted to yourvehicle, your tyre fitter may need to programme thenew component to the car using specialist diagnosticequipment.

Our centres have the testing equipment required to service & replace TPMS valve sensors. We have found one of the main reasons for prematurely replacing TPMS valves sensors is the use of metal or aftermarket valve caps, whereby, when trying to remove the valve cap the valve stem snaps because the cap has corroded itself onto the valve stem. It is recomended to only fit plastic or alloy valve caps. If this happens to you it’s not always a case of replacing the whole sensor, though we can if required. We are able valve sensor service kits to replace just the valve stem & seals in many cases.

If your TPMS sensor develops a fault, under nocircumstances should the sensor be removed and replacedwith a ‘standard’ non-TPMS type valve. Removing thesensor will not only reduce your safety on the road,it will also result in your car failing the MOT.

Ground was broken today within our Bush Tyres Beverley depot and for good reason, the work which is planned to be completed by early Spring will see a new MOT Station installed.

The wait for Ascenso’s first radial Earth Mover Tyre to be fitted in the UK is finally over. On Monday 9th February A small team from Toby Clowes was sent to one of Welton Aggregate’s active processing sites on Spa Road in Lincoln.

The Ascenso Excellence Award is a recognition of the hard work and dedication of the Bush Tyres agricultural team.

Tyres

Tyres Services

Services Fast Fit

Fast Fit Offers

Offers